- Home |

- Senior Design Program

Senior Design Program

Help Students Help You

Do you have an engineering problem you want solved in your company or small business? Sponsor a senior design project, and a team of senior students will work on it applying all the knowledge they have acquired in a challenging, real-world environment.

The Senior Design Program is an advanced course on systems design, integration, and best practices for use of machine elements such as bearings, springs, gears, cams, mechanisms, etc. Modeling and analysis of these elements is based upon extensive application of physics, mathematics, and core mechanical engineering principles (solid mechanics, fluid mechanics, manufacturing, estimation, FEA, etc.). These principles are reinforced via a substantial design project where students model, design, fabricate and characterize a mechanical system that is relevant to a real-world application. Project management, utilization of standards, oral presentations, and engineering reports are required.

Students will work in a group of 4 to 5 on your project and will be mentored by both an instructor and an industrial mentor to find a solution to your engineering problem.

Senior Design Team

Wil Whittington

Assistant Professor

Jack Perkinson

Dalton "Ross" Smith

Instructor

Jarachi Maroune

Teaching Assistant

We do projects at all levels

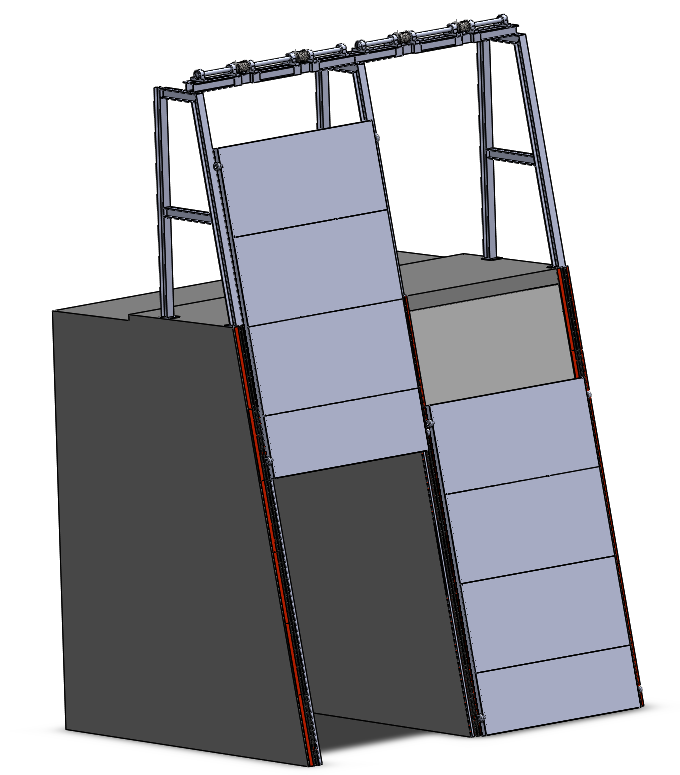

Customer: Winston Plywood & Veneer

Project: Vault Door Opening System

Group: Door Solutions Engineering

Date: Spring 2019

Winston Plywood & Veneer needs a new vault door system that will be used to soften and condition the cut logs inside a homogenizing chamber. The current door is failing due to unwanted stress and steam is escaping from the chamber. A new redesign with corrosion resistant materials, epoxy to help prevent crack propagation, and structure modifications to better handle the loads was proposed.

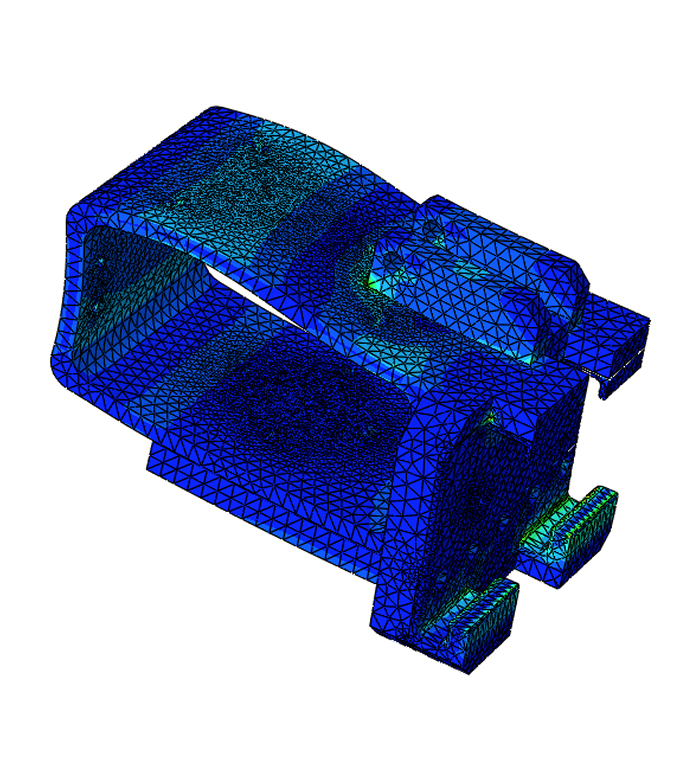

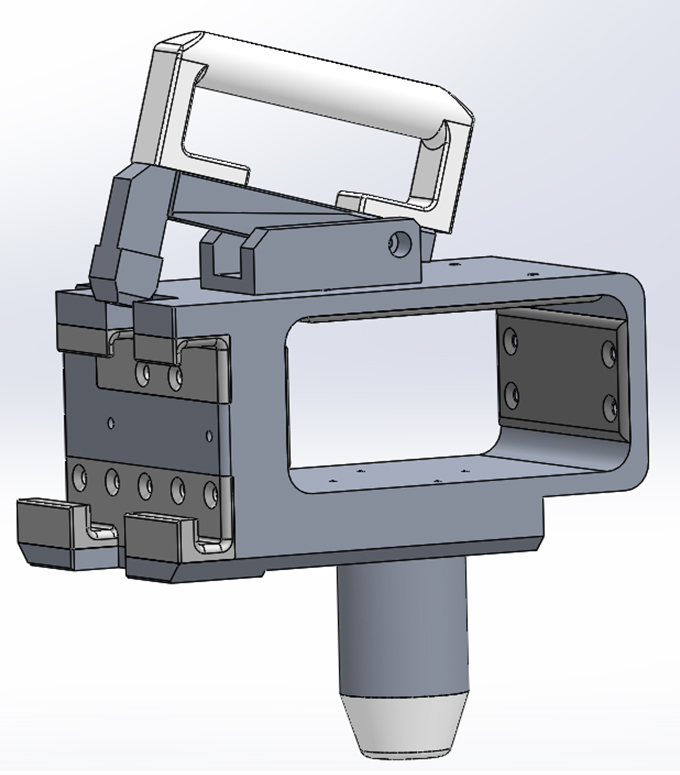

Customer: PACCAR Engine Company

Project: Pallet Shoe Attachment

Group: Atlas Attachments

Date: Spring 2019

Paccar needed a redesign of their palletshoes, which are used to pick up an engine and pallet by use of a forklift. The goal is to reduce the overall weight by about 50% to improve the ease of use on the operator, while maintaining structural integrity, safety, and lifting capacity. New aluminum design proposed with both4140 PH steel and Delrin inserts to protect it from wear. FEA analysis proved that structural integrity is maintained while reducing the weight by more than 50%.

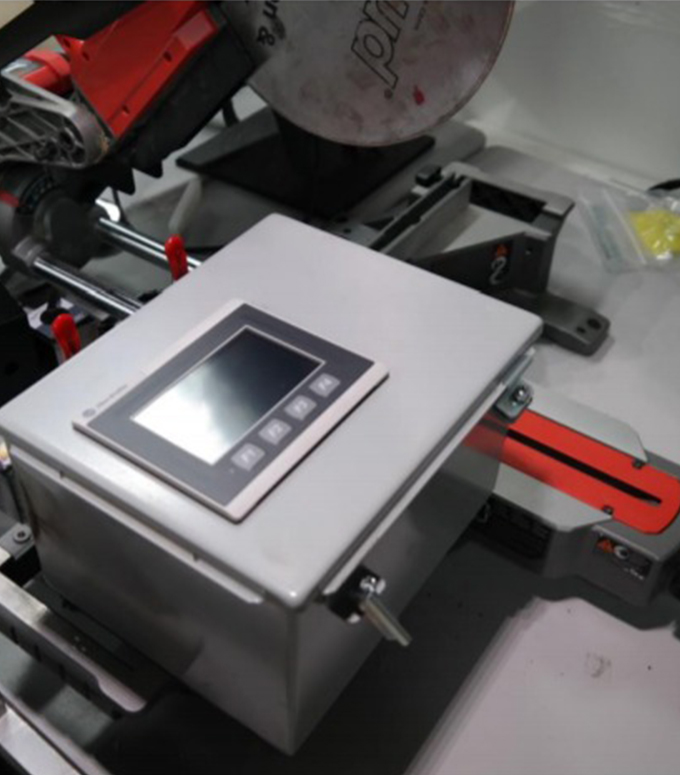

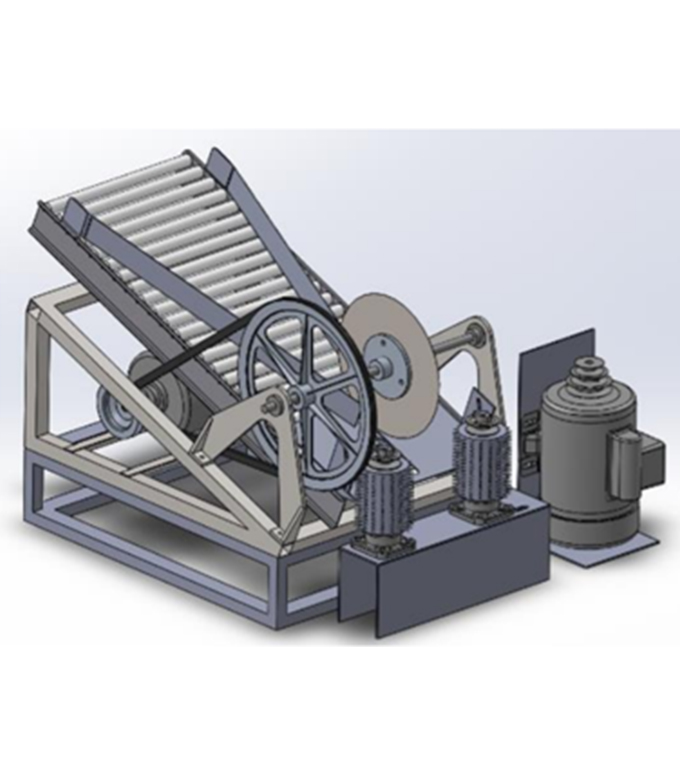

Customer: Milwaukee Tool

Project: Miter Saw Blade Tester

Group: Mechanical Systems Analysts / Everest Elites

Date(s): Spring/ Fall 2019

Milwaukee Tool needed a testing fixture to test the ability accuracy and functionality of its M18 Fuel Miter Saw. Testing fixture needs to prove that the miter saw is functioning as necessary by eliminating the need of manual test with visual inspection.A final intuitive and easy to use design consisting of a laser displacement sensor was made to measure the variation of a blade as it spun.

Customer: 360 Knee Systems

Project: Multi-Axial Load Cell Prototype

Group: Load Cell Consultants LLC

Date: Spring 2018

360 Knee Systems needs a handheld multi-axial load cell to find this applied force. This device would measure the loads and moments applied to the handle of the device for use in calculating knee laxity.A load cell was made that gives accurate load readings in both live and data-logged form. The load cell was fixed to a boot and adjusted to make it comfortable when worn by the patient.

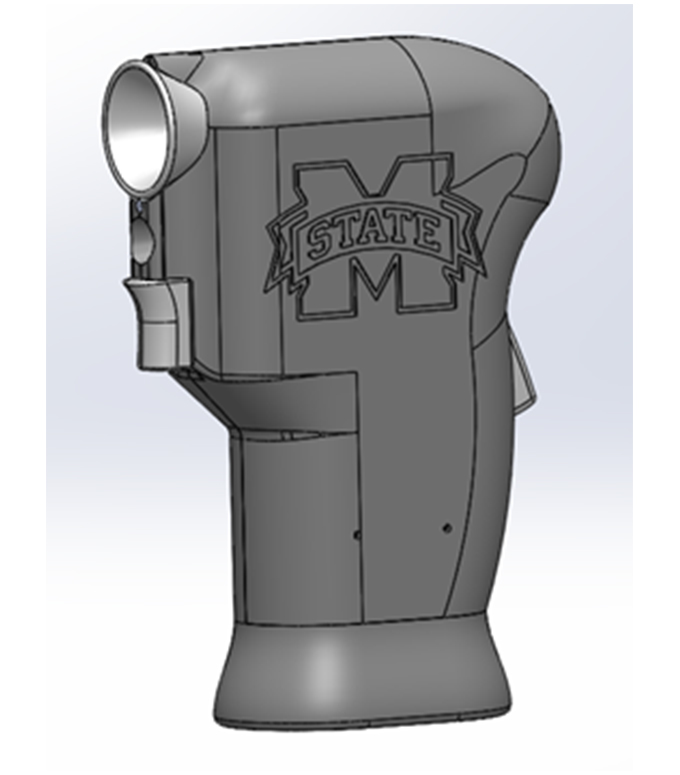

Customer: Multicraft Ventures / Larry Rowlett

Project: VIPR Gun

Group: Level 5 Engineering

Date: Fall 2018

Former Secret Service Agent, Larry Rowlett, partnered with Multicraft Ventures to develop a multi-functional single action self-defense system incorporating three common non-lethal deterrents. These include pepper spray, strobe lights, and an air horn. Level 5 Engineering was tasked with creating a design for the VIPR Gun. The VIPR Gun must be able to deploy all three deterrents at once, designed for left and right hand users, be rugged enough to withstand harsh conditions, and be safe for the user. Level 5Engineering’s final design included a mechanism to propel pepper spray up to replaceable canisters for the pepper spray up to 10 feet, an air horn which produced an intense sound (5000 Hz at 95 dB) from 10 feet away, and designed to allow for replaceable pepper spray canisters.

Customer: MSU Alumni

Project: Automated Ringing Cowbell

Group: Everybody Rings

Date: Spring 2019

No Mississippi State football game is complete without the ringing of cowbells. This is an almost sacred tradition to the fans of MSU football, however, some fans are unable to participate. Everybody Rings was tasked with creating a cowbell that could be rung at the push of a button so that fans, despite physical ability, could participate in the tradition. A cowbell was purchased and fitted with a ringer assembly consisting of an electrical circuit, battery, and push-button operating switch. Everybody Rings partnered with the T.K.Martin Center and the MSU Entrepreneurial Center to develop a startup company.

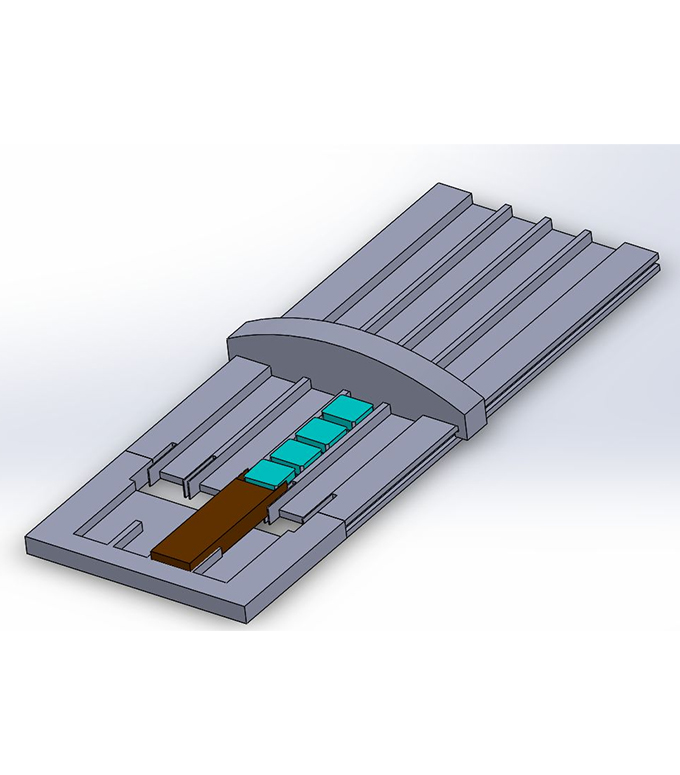

Customer: GLO Pals

Project: Packaging Workflow Improvement

Group: Glo UP

Date: Fall 2019

GLO Pals creates and packages Glo Light UpCubes. Currently, the process of packaging Light Up Cubes involves unpacking the cubes from trays shipped from a manufacturer in China, dumping the cubes from the tray onto a table, and manually sorting and packaging the cubes into sleeves of 4. Glo Up was tasked with improving the flow of packaging GLO Light-Up Cubes. To do this, the team has designed and fabricated a mechanism into which the cubes can be dumped without having to be sorted. This mechanism also allows for the sleeves to be pre-formed onto the ends of the line of cubes. With this, the cubes can be pushed as a single unit instead of one at a time, drastically reducing the packaging time.

Customer: Tilley Family Farm

Project: Bread Packaging Separator

Group: Some where Over the Grainbow

Date: Spring 2019

The Tilley Family Farm partnered withSomewhere Over the Grainbow to produce a mechanism that could remove the plastic packaging from sliced bread, bagels, etc. and provide an operating manual. This machine would shave off hours of work for small farms who use the bread products to feed their livestock. An assembly was created which consisted of a chute for the packaged product to be placed in, a deli saw connected to a 0.5hp engine to saw the bread in half, and two spiked rollers connected to the engine which would catch the plastic packaging and tear it away from the bread. A protective cage would be placed around the assembly in order to maintain safety of the operators.

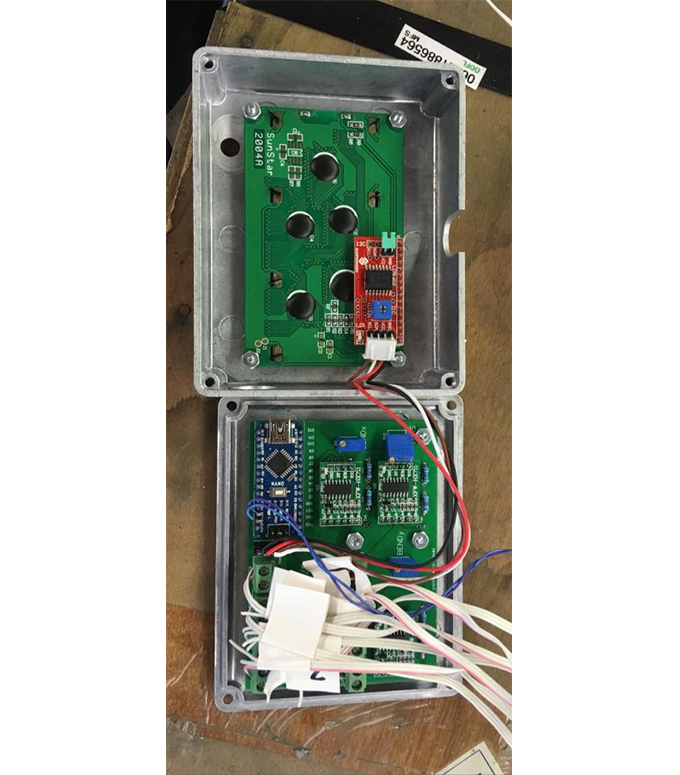

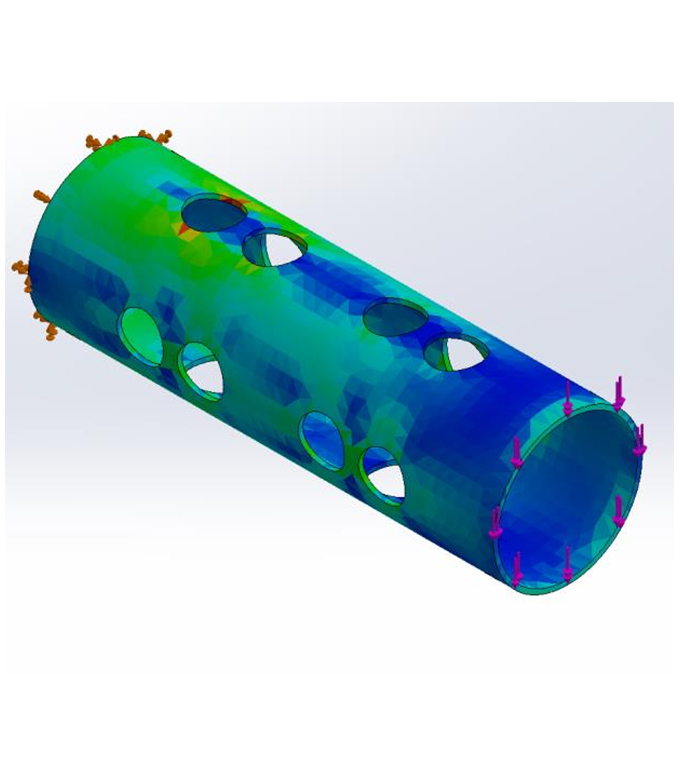

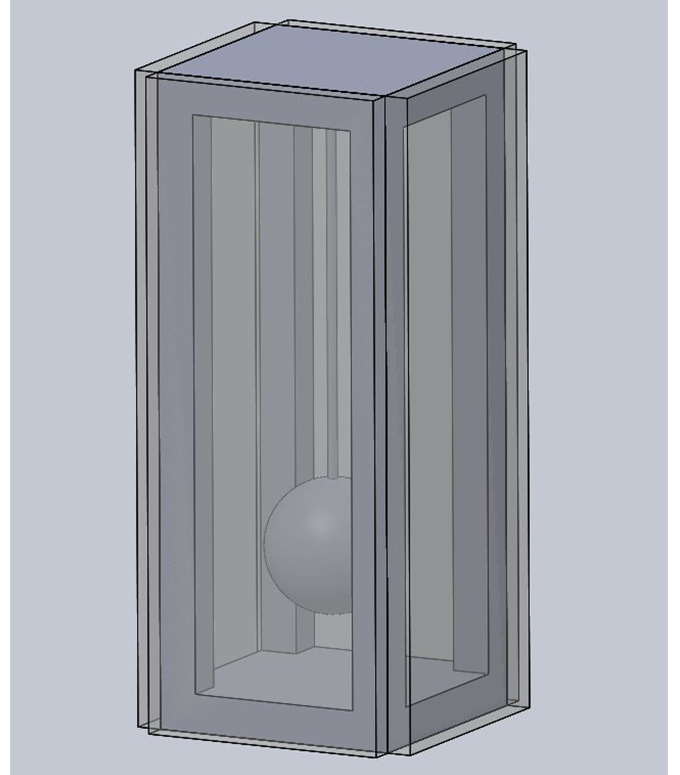

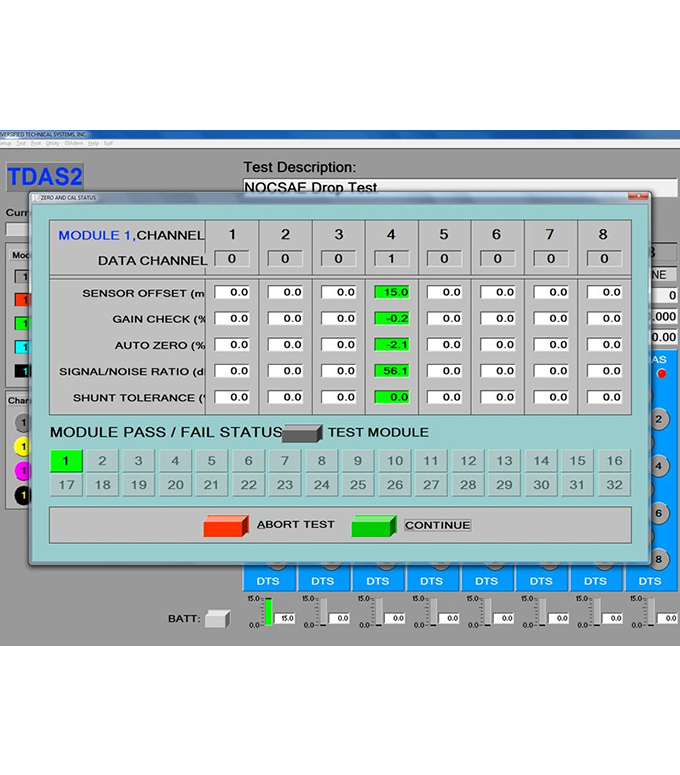

Customer: LosAlamos National Laboratory (LANL)

Group: DeltaV Design (DVD)

Project: AccelerationTesting Device

LANL requested the team to design, fabricate, and test an acceleration device to record and output the magnitude and direction of acceleration in at least two coordinate axes. The device also needed to move freely to simulate nonlinear vibrational responses. DVD proceeded to research similar studies involving mass-spring-damper systems which could provide similar responses and finding systems that behave similarly under vibrational responses (ex: radio towers). A final design consisting of a nested cylinder with a stainless steel pendulum acting as the input force for acceleration was modeled and fabricated. To test the system a pvc housing was created to suspend the cylinder in the air, allowed the pendulum to be lifted and strike the system, and also house the accelerometer needed to gather data. Data collected from the tests was compared to an FEA analysis of the system to determine the accuracy of the calculations.